This subject was just asked about and I happened to do it yesterday, so I thought I'd post how. I did a lot of searching and came up with bits and pieces of info, enough to do it. cost me under $10

![Image]()

![Image]()

the original wastegate

![Image]()

ground the crimp seam till i could see the joint and begin to split it. It took a lot of grinding to get it down to that point

![Image]()

finally split, then i ground it all down smooth. I marked the rod where it normally sits flush, entering the vac pot to mac sure i left it approximatly long enough. then I drilled out the rivet holding the diaphram

![Image]()

took a 3/8" carrage bolt and cut it to be about 2 1/2" long. then I drilled a pilot hole in it to put the end of the rod in. put the rod back in the vac pot half and welded the stud to the end of it. If you don't have a welder, cut the rod in half, thread it and put in a turnbuckle piece to extend and contract it.

![Image]()

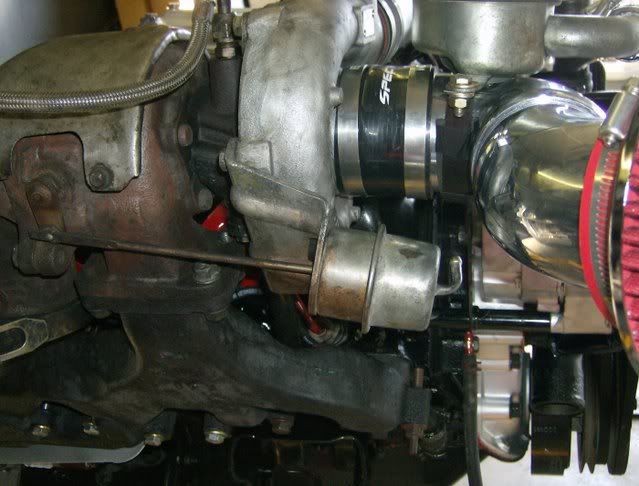

then i installed it back on the turbo and installed the spring, and nuts. I have a nylock nut on it to stop movement. I bought a set of tarp grommets and used the inner half to keep the sping centered. You can see this as the brass piece with a collar protruding inside the spring. the spring was 2 1/2"x5/8". available at home depot in their bulk assortment bins.

IMORTANT... don't do this without a pyro and a boost gauge, or you'll burn or blow it up

the original wastegate

IMORTANT... don't do this without a pyro and a boost gauge, or you'll burn or blow it up