I have heard the advice about drilling the cap. I drilled a hole in my cap when I had some issues. I have since fixed the issues and I replaced the cap with a new diesel cap. I replaced my cap with

Amazon.com: Stant 10819D Diesel Fuel Cap: Automotive

This is the part I do not get, the system is for the most part a closed loop system. The purpose of the cap is to relieve the loss of volume (diesel) due to it being injected into the cylinder. Diesel fuel caps are designed to hold a little vacuum ~1 PSI.

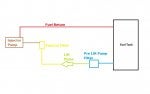

If the system is negative 1 psi it is operating at negative 1 psi across the entire system, tank to injector pump back to tank. The net effect is it cannot put more strain on the lift pump. Example:

With lift pump off the system will equalize. You will have -1 psi before and after the lift pump. When you power the lift pump you will get a pressure differential pre/post lift pump, pre/post filters due to restrictions and the movement diesel. If your lift pump was capable of generating 9 psi pressure difference it will still generate 9 psi while having the entire system still at -1 psi. The lift pump will not know it is operating under a vacuum since the entire system is under the same vacuum.

In theory you might measure a lift pump pressure output loss of 1 psi. The loss of 1 psi is due to the entire system having a vacuum of 1 psi. If you adjust the measured value to account for the system vacuum you still have the 9 psi output of the lift pump.

I agree that if you have a small leak allowing air into your fuel system drilling the cap to relieve the system vacuum could help prevent air getting into the system.

If you have a malfunctioning fuel cap I can see collapsing the fuel tank as you drive.

I guess my question is, did GM have a reason to operate the entire system at negative 1 psi? Could it be that the system vacuum helps with cavitation, to evacuate air bubbles from fuel or to help keep the system clean?

Any thoughts or am I crazy?

Brian