I will try to answer some questions about certain aspects of the heads and valvetrain. First, the valves are stock 6.2 J code size. They look larger because the 45 degree reliefs around the valves have been opened up. This does two things: it unshrouds the valves at low lift, and it increases chamber volume. As a result of the latter this engine has an 18:1 compression ratio with stock height pistons. The common method of dropping the piston .030" in the hole to get 18:1 leaves you with less "squish" and slower moving air in the cylinder. My method increases low lift valve flow and maintains the high cylinder turbulence of a stock compression engine (at least, that's the theory).

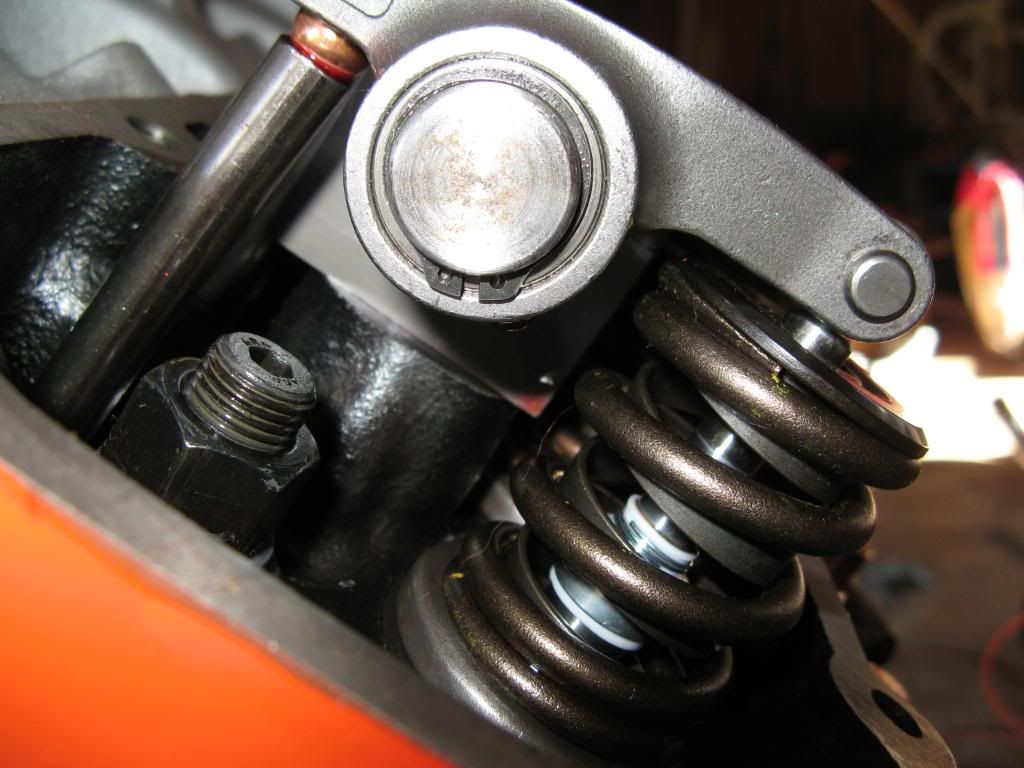

The valve springs are comp cams. They give 109# seat pressure (vs 80# for stock springs) to reduce the chance of valve float in case of an accidental overspeed (i.e. missed shift). The retainers and keepers are also Comp, and are 10 degree performance type. In order to maximize valve life both intake and exhaust are fitted with rotators. Since the stock 6.2 rotators fit smaller springs I had to use big block rotators. Their diameter and height required machining of the spring pockets and stems.

I was unhappy with the induction hardened seats and rather loose guides in the heads, so I replaced both with superior aftermarket pieces. The guides are sintered iron with spiral oil retaining grooves inside, and are topped with teflon positive seals. The intake seats are hardened steel, while the exhausts are a high temp nickel alloy designed for use with the stellite faced exhaust valves. The valves themselves are made by SI, and are their HD replacements for J code 6.2's. It should be noted that the use of seat inserts in the exhaust side will positively prevent the formation of a crack between the exhaust and intake valves. This crack is caused by the high operating temp of the integral induction hardened seat (which is brittle and crack prone) while being pounded incessantly by the valve. IH had the exact same problem with their prototype 6.9's, and they solved it by using seat inserts.

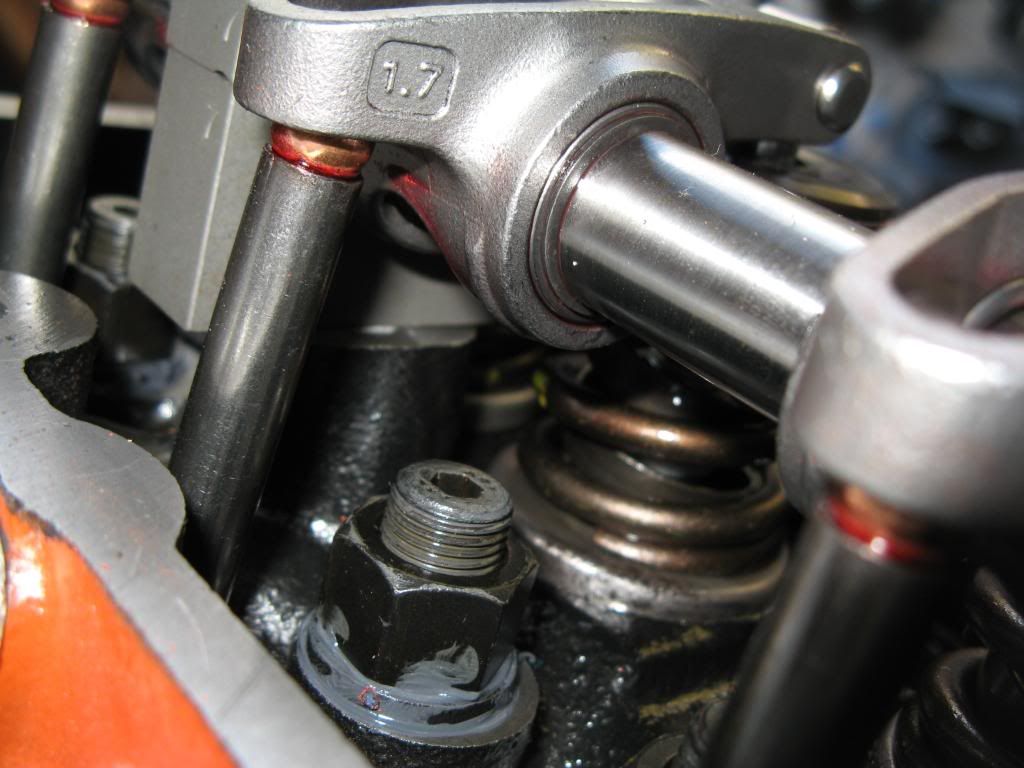

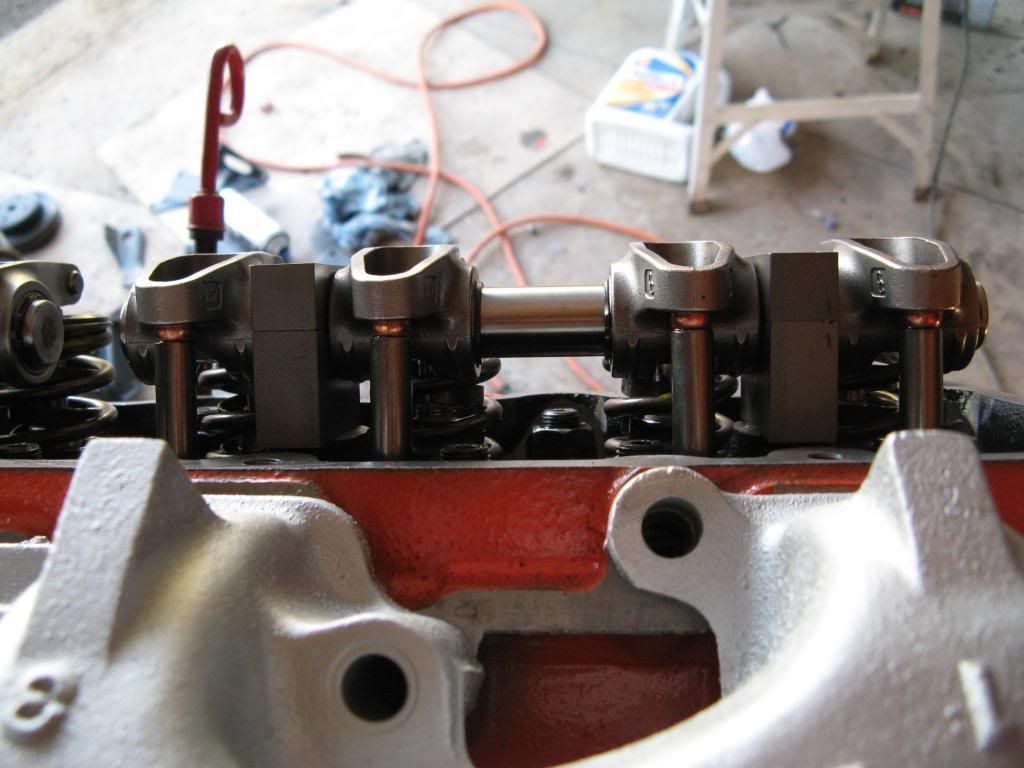

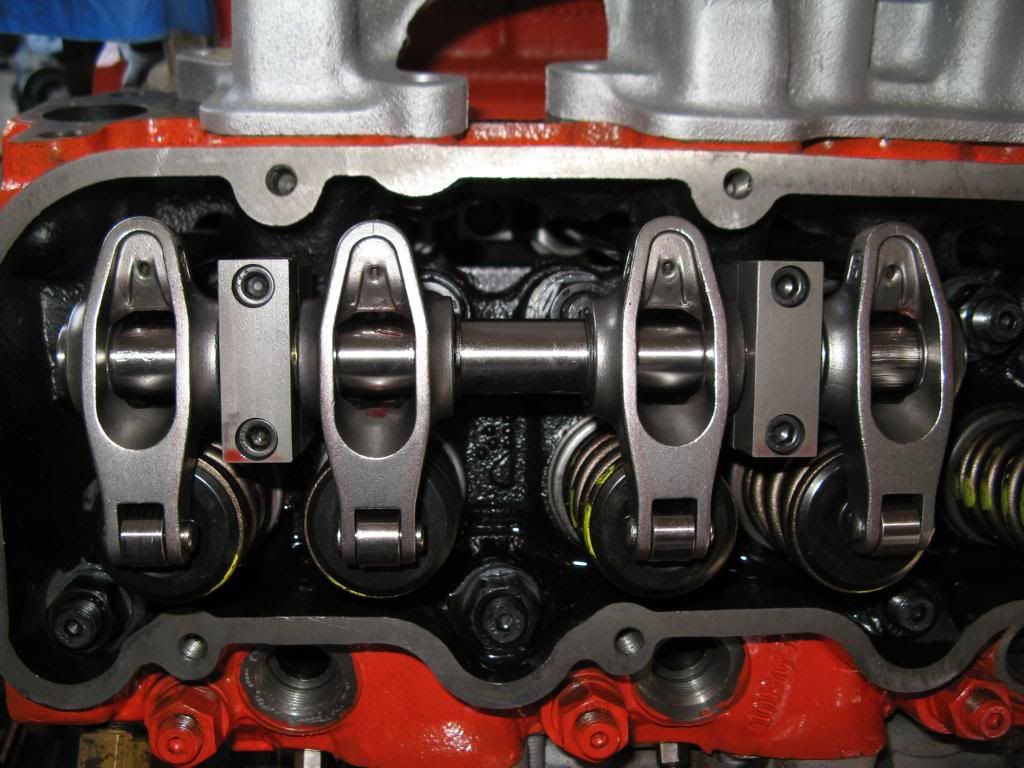

The rocker arms are Comp Cams magnum roller rockers. They are 1,7:1 ratio big block units. I removed the trunnions in them so I could mount them on shafts. The shafts themselves are made from ground O1 tool steel hardened to 60-62Rc. This hardness is needed so the needle bearings don't brinell the shaft and eventually destroy it. The shaft pedestals are made from 1018 that has been carburized (case hardened) to 60-62Rc for wear resistance (the rockers can rub on the sides of them). They have caps aligned to the bodies with 1/8" dowel pins, and each body/cap pair is numbered and fitted as a pair, similar to rods and their caps. They are mounted to the head using special studs that have 1/2-13 threads on one end and 3/8-24 threads on the other. The studs are machined from 17-4 stainless steel and precipitation hardened to give a strength of 200ksi (for comparison, standard ARP fasteners are 160-170ksi). They are retained with thin walled ARP 12 point nuts. I even had to machine down a socket to fit in the tight well - a standard socket has walls that are too thick. Besides holding the shafts, the mounts also offset them toward the intake side of the heads. This is necessary because the distance between the fulcrum and roller tip is greater with these 1.7 rockers vs. the stock 1.5 rockers. The pushrods are new Sealed Power stock length 6.2 pushrods. Pushrod geometry is identical to a stock engine since the roller tip to rocker ball distance on the big block is nearly identical to the diesel.

Since these rockers are higher ratio the valves gain more lift. Valve lift on a stock 6.2 is .420". With the 1.7 rockers it increases to .476. Piston to valve clearance was checked and, while VERY close, it is better than the specs for the International 6.9. The 6.9 gives an exhaust-to-piston vlearance of only .009"! This is WAY too close IMO, and thankfully the advance built into the 6.2 cams gives around .030". The intake is much tighter, but it can be since the piston is retreating from the valve. Exhaust clearance is much more critical in any engine because the piston is approaching a retreating valve, and any valve float risks a collision. This doesn't happen with the intake valve. BTW, as a point of comparison gassers, especially race motors, try to have at least .100" clearance between the exhaust valve and piston at their closest approach. This is because valve float and lifter pump-up is much more likely with a high revving gas engine.

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()