Hello,

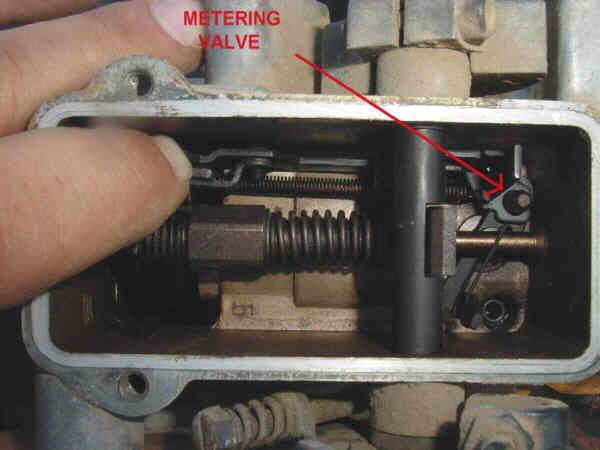

i need to replace the metering valve on my DB2 IP. After a year of a very specific symptom i am just about positive that it must be done - the valve is getting stuck when the engine is hot while running diesel but once i switch to veggie it runs perfect. It will get stuck in idle, not at highway speeds, and it starts more or less fine at all temps, 190 F down to 0 F.

Adding some veggie to the diesel tank helps a lot but did not totally solve the problem.

Anyway, does anyone know what the possibilities of switching out this valve with the pump still on the engine would be? I spoke with one tech who said it could be done if you are really careful and if you know what you are doing. It would be a stretch to say "i know what i am doing" but that has never held me back before.

what do you think? anyone ever try this?

thanks,

Paul

i need to replace the metering valve on my DB2 IP. After a year of a very specific symptom i am just about positive that it must be done - the valve is getting stuck when the engine is hot while running diesel but once i switch to veggie it runs perfect. It will get stuck in idle, not at highway speeds, and it starts more or less fine at all temps, 190 F down to 0 F.

Adding some veggie to the diesel tank helps a lot but did not totally solve the problem.

Anyway, does anyone know what the possibilities of switching out this valve with the pump still on the engine would be? I spoke with one tech who said it could be done if you are really careful and if you know what you are doing. It would be a stretch to say "i know what i am doing" but that has never held me back before.

what do you think? anyone ever try this?

thanks,

Paul